ENGLISH

NOAH HOLDNINGER

DANISH

Information about Carbon Capture and Storage - CCS

CLIMATE EFFICIENCY

Energy companies boast that CCS is going to save the climate from large volumes of CO2. Reductions between 85% and 95% are heard again and again. Reduction rates of this magnitude, however, are theoretical reductions achievable exclusively in the capture stage of the CCS process. Little is said about the substantial greenhouse gas emissions resulting from the total CCS process.

CCS has a number of built-in limitations when all activities required to operate a power plant with CCS is considered: greenhouse gases are emitted in extraction and transportation of extra fuel, construction of plants, capture of CO2, transport of captured CO2, injection and storage of captured CO2 and monitoring of storage.

The environmental pressures from each of these activities depend on factors such as additional energy use in the capture process - often referred to as the energy penalty, - types of fuel, capture rates, purity requirements for captured CO2 and distance between point source and CO2 storage. The additional energy is the extra energy needed to deliver the same output from a coal-fired power plant with CCS compared to a situation without CCS plants. It is not feasible to calibrate the climate impacts of each of these activities precisely because no coal plants with CCS at full scale exist at present.

The following assessment is based on conservative assumptions. The core part of the CCS technology is the capture process in which an additional amount of energy in the order of 40% will be consumed. The figure of 40% is a mean value of a number of sources covering a wide range of estimates. See this survey.

An additional amount of energy in the capture process of 40% implies a proportional consumption of energy and CO2 emissions in all other stages of the CCS chain.

How much CO2 can be reduced with CCS?

The question that must be answered is: How efficient is the CCS technology when it comes to reducing greenhouse gas emissions measured as CO2 per. GJ at coal-fired power plants ? In order to answer this question all processes that involve emissions throughout the CCS technology chain should be identified. These are:

- Mining of coal

- Transportation of coal

- Construction of CCS plant

- Operation of CCS systems (capture)

- Construction of transport infrastructure for the captured CO2

- Transport and injection of captured CO2

- Control and monitoring of storage facilities

- Leakages

CO2 emissions are bound to increase in the first two processes as a result of CCS. How much depends on the additional consumption of energy in the capture process. The other processes are integrated elements of the CCS technology, without which it can not function. See this FIGURE of the CCS chain.

Each step in the chain represents an extra consumption of energy and an amount of emissions that should be counted in order to obtain a realistic picture of the total climate impact of CCS.

Emissions

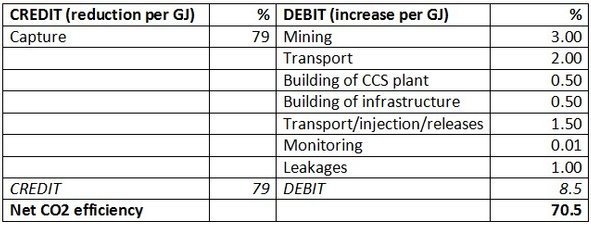

The problem can be expressed in a simple accounting system with a credit side covering reduction effects (in the capture process) and a debit side covering CO2-enhancing effects of CCS.

The theoretical efficiency of 85% falls to 79% if the additional energy consumption in the capture process is 40%. Debit emission rates are preliminary assessments. Based on these preliminary figures the overall CO2 efficiency of CCS is 70.5%.

The credit side

Operation of CCS facilities - the capture process is the key process that captures CO2 from the flue gas. An amine compound (absorbent) reacting with the CO2 is often used. The downside is, firstly, that a very high temperature is required - and consequently large amounts of energy - to release CO2 from the amine compound, so it can subsequently be purified and compressed to liquid storable CO2. Secondly, only a portion of the CO2 in the flue gas reacts with the absorbent and therefore a significant portion of CO2 escapes, together with all other substances in the flue gas that CCS does not capture. There is a long way from the stipulated 60-75% CO2 reductions in the capture stage at test scale facilities to the theoretical 85-95% stipulated in full-scale installations. The high level of energy consumption and low reduction rates make it hard to see how it should be possible to capture CO2 from a full-scale coal plant with CCS with an efficiency of 85%-95%. The operation of a CCS plant involves consumption of energy and CO2 emissions associated with combustion, compression, separation and purification. These should be deducted when net CO2 effects are calculated.

The formula for CO2 emissions per GJ in the capture stage can be expressed as follows:

kg CO2/GJ * (1 + additional consumption) * (1-capture efficiency).

With an emission factor of 95 for coal combusted at a coal-fired power plant (95 kg CO2 emitted per GJ), an additional amount of energy of 40% and a capture efficiency of 85% gives:

95 * 1.4 * 0.15 = 19.95 (kg CO2/GJ), which means that the net capture efficiency of CO2 is 19.95 kg per GJ produced at the power plant.

This corresponds to (19.95 / 95 * 100) = 21% or a net efficiency of (100-21) = 79%.

The 40% extra energy in the capture process reduces the CO2 reduction rate from the preconditioned 85% to only 79%.

The debit side

Mining of coal. This involves operation of heavy equipment. CO2 emissions occur as a result of combustion of diesel and gasoline and to a lesser extent from the production of electricity, which may be based on coal, gas, oil or even renewables. In addition, cleaning, sorting and handling involve CO2 emissions associated with the combustion of diesel. The amount of emissions depends on the additional energy consumption in the capture process. Is this 40% extra compared to a situation without CCS, roughly 40% more coal must be mined and handled and the resulting emissions shall be deducted from the CO2 reduction in the capture process.

Transportation of coal by ship, rail or road leads to CO2 emissions associated with combustion of diesel and heavy fuel oil. Most coal transportation combine the three forms of transport. The level of emissions at this stage depends on the energy consumption in the capture process. Based on the abovementioned 40% a corresponding extra amount of coal must be transported and emissions from this extra transport should be deducted from the reduction of CO2 in the capture process.

Construction of the CCS plant on a commercial scale will involve significant emissions of CO2 associated with the manufacture and transportation of cement, concrete, metal etc. as well as in relation to the processing and construction, building and installation of machinery. Energy processes are numerous and heterogeneous resulting in CO2 emissions from a wide range of fossil fuels (oil, coal, gas, diesel, gasoline etc.). A quantification will require a genuine life-cycle analysis of each full-scale plant. Quantified CO2 emissions should be ascribed to CCS ie. added to the overall CO2 emissions in the technology chain.

Construction of transport infrastructure involves the manufacture and transportation of pipes, excavation and installation which leads to emissions of CO2 that should be deducted from achievable CO2 reductions in the capture process.

Transport and injection of captured CO2 for storage result in emissions associated with boosting and pumping. Energy consumption and CO2 emissions captured and stored CO2 at this stage should be subtracted from the CO2 reduction in the capture process.

Control and monitoring of storage facilities involves operation of buildings and machinery. CO2 emissions from such activities should be subtracted from the CO2 reductions in the capture process.

Leakages include leaks from storages and accidents at pipelines, ships and CO2 injection facilities. Such releases should be subtracted ton by ton from CO2 reductions in the capture process.

Summary

At a 40% additional energy consumption in the capture process the assumed rate of reduction declines from 85% to 79%. When estimates of climate impacts from other activities necessitated by CCS are taken into account the total reduction efficiency drops to 70.5%. This has profound implications for the reduction contributions that can be expected from this technology. Wuppertal Institute for Climate, Environment and Energy, RECCS: ecological, economic, and structural comparison of renewable energy technologies (RE) with Carbon Capture and Storage (CCS) - an integrated approach arrives at a greenhouse gas reduction efficiency in the range of 67 % -78% depending on fuel type and process. Based on the abovementioned CCS as a whole will only be able to reduce somewhere between 2/3 and 3/4 of climate impacts from coal-fired power plants, which means that even after huge investments in CCS between 1/3 and 1/4 of emissions from coal-fired CCS plants could not be avoided.

This calculations are solely an isolated view about one single power plant equipped with CCS. It does not give a true picture of the global effects from a mitigation pathway with a strong emphasis on CCS.

In 2010 NOAH Friends of the Earth Denmark published an assessment of the CO2 reductions at all power plants expected to be retrofitted with or built with CCS from 2010-2050. The main finding was that only 11% of the cumulative CO2 from all these plants will be avoided from the atmosphere in the course of the four decades.